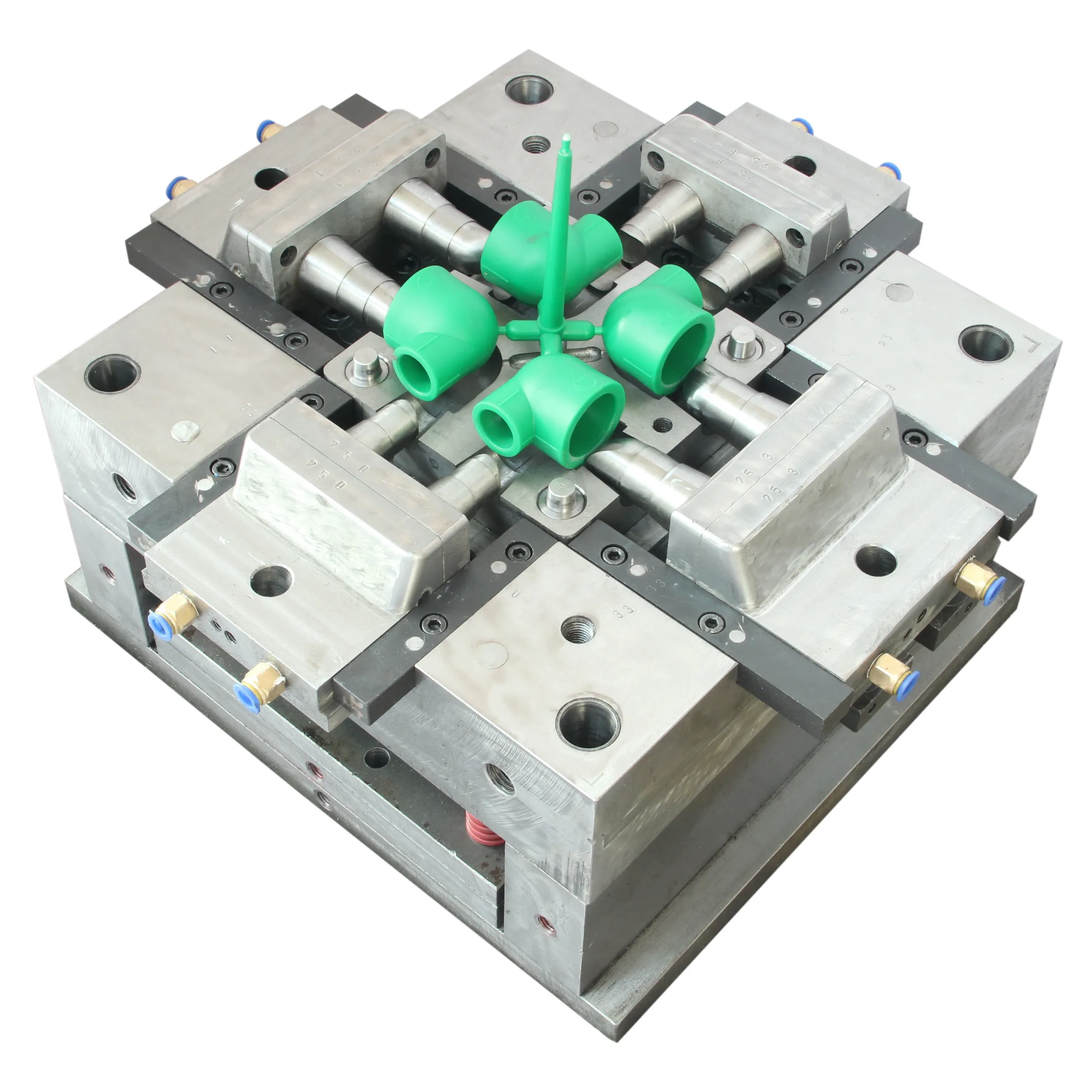

PP-R Reducing Socket Pipe Fitting Mould

Mould name: PP-R Reducing Socket Pipe Fitting Mould

Cavity:4 cavities

Mould size:20-63mm

Mould steel:2738 or 718for the cavity and core

Gate :direct gate

mold structure: Diagonal guide column slider structure

Hardness of core/cavity: HRC 32-45 degree after vaccum heat treatment

Injection molding machine:320T

Taizhou Huangyan Hong Jin mould Co., Ltd was established in 2002.We are professional in design and manufacture the pipe fitting mould for more than 23 years.

We are looking forward to long cooperation with you.

Following is the main information for your reference.

FAQ:

1.What is your MOQ?

1 set is Ok

2.What is your delivery time?

The time of delivery is around 60-75 work days.

3.What is the shipping port?

MOULD ship to Ningbo or Shanghai port are ok.

4.What is your payment terms?

We accept 40% T/T in advance,balance 60% TT before shipment

5.How should I contact you?

You can contact me by email whatsapp or wechat

FAQ:

1.What is your MOQ?

1 2 3 set is ok

2.What is your delivery time?

The time of delivery is around 60-75 work days.

3.What is the shipping port?

We ship mould to Ningbo or Shanghai port.

4.What is your payment terms?

We accept 40% T/T in advance,balance 60% TT before shipment

5.How should I contact you?

You can contact me by email whatsapp or wechat

So how about edge gate for the mould

Its gate is a little bigger than submarine gate. The product cycle time is short. But the gate cannot be separated from the product, so it need worker to cut. And product surface looks not so well.

Common specifications:

20 × 25 (4 minutes to 5 minutes)

25 × 32 (5 minutes to 6 minutes)

32 × 40 (6 minutes to 1.2 inches)

40 × 50 (1.2 inches to 1.5 inches)

50 × 63 (1.5 inches to 2 inches)

63×75

75 × 9020 × 25 (4 points to 5 points)

25 × 32 (5 minutes to 6 minutes)

32 × 40 (6 minutes to 1.2 inches)

40 × 50 (1.2 inches to 1.5 inches)

50 × 63 (1.5 inches to 2 inches)

63×75

PPR reducing socket pipe fitting mould feature

1. Automatic motor driven .

2. Interchangeable insert design.

3. Cavity and core steel use hardened stainless steel.

4. Balanced runner layout for the even injection flow.

5. Unique gate deigns for fast injection flow.

6. Optimal cooling system for faster cycle time.

7. Tailor made solution for the irregular shape pipe fittings.

Manufacturing process of pipe fittings

One of the main processes in manufacturing pipe fittings is injection molding. Equipment to mold accessories include a mold and an injection molding machine.

The mould is a split metal and a block cavity formed by processing. Dimples in a mold part are created by the tool that shapes the cavity of the part. A molded part is created by filling the cavity in the mold with a filler called a gate. According to the parts to be manufactured, the injection mold can be composed of multiple cavities and multiple gates.

And the parts are usually hollow. In order to make the inner surface have enough quality, the design of pipe core is very important, which is very important for the applicability of pipe fittings

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED