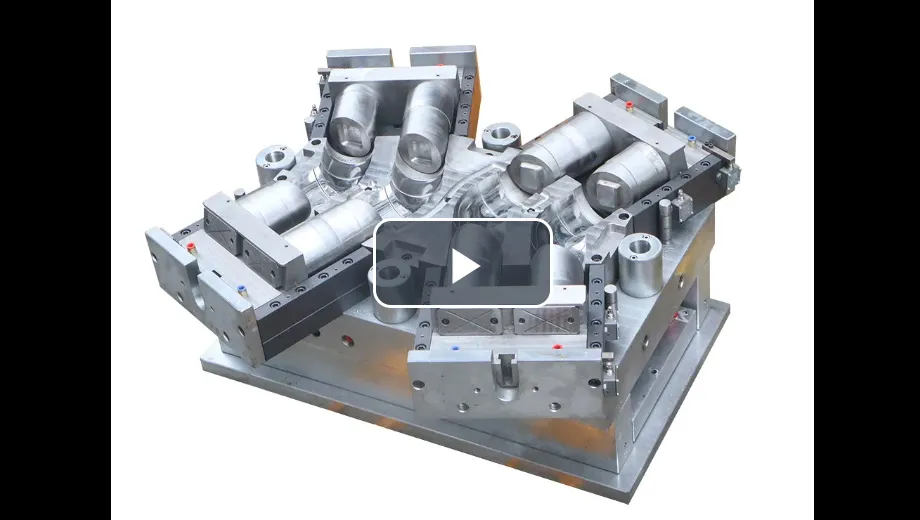

90 Elbow Injection Mold

90° Elbow Injection Mold: Design and Manufacturing Overview A 90° elbow injection mold is a specialized tool used in plastic injection molding to produce 90-degree elbow fittings, commonly found in piping systems for fluid or gas transport. These fittings require precise dimensional accuracy, smooth internal surfaces, and high durability to withstand pressure and environmental factors. The mold design and manufacturing process must account for material shrinkage, cooling efficiency, and ease of demolding to ensure consistent part quality. Key Design Considerations 1. Part Geometry: The 90° elbow’s curved shape necessitates a multi-cavity or family mold design to balance flow paths and minimize warping. Core and ejector systems must align with the bend radius to avoid deformation during demolding. 2. Material Selection: Mold steel (e.g., P20, H13) is chosen for its wear resistance and thermal stability. For high-volume production, hardened steel or coatings (e.g., DLC) extend mold life. 3. Gating System: A hot runner system is often preferred to reduce material waste and ensure uniform melt distribution. Sub-gates or pinpoint gates are positioned to avoid weld lines in critical areas. 4. Cooling Channels: Conformal cooling channels follow the elbow’s contour to accelerate cycle times and prevent uneven cooling, which could cause sink marks or warpage. 5. Ejection Mechanism: Angular lifters or collapsible cores may be used to release the undercut geometry smoothly without damaging the part. Manufacturing Process - CNC Machining: High-precision milling and EDM (electrical discharge machining) create the mold cavities and cores with tight tolerances (±0.02 mm). - Surface Finishing: Polishing or texturing is applied to achieve the desired part surface (e.g., smooth for fluid flow or textured for grip). - Testing & Validation: Trial runs verify fill balance, cooling efficiency, and part dimensions. Adjustments to gate size or cooling layout are made as needed. Challenges & Solutions - Warpage: Optimized cooling and uniform wall thickness mitigate distortion. - Flash: Tight shut-off surfaces and proper clamp force prevent material leakage. - Cycle Time: Conformal cooling and automated ejection reduce production time. Applications 90° elbow molds produce fittings for plumbing, automotive, and industrial systems, typically using materials like PP, PVC, or PEX. The mold’s durability and precision ensure compliance with industry standards (e.g., ASTM, ISO). In summary, a well-designed 90° elbow injection mold combines advanced engineering with meticulous manufacturing to deliver high-performance plastic components efficiently.

Products

Category:

-

PVC Elbow 45°pipe Fitting Injection Mould

Category: PVC pipe fitting moldBrowse number: 488Number:Release time: 2025-10-28 21:16:52PVC Elbow 45°pipe Fitting Injection MouldMould name: PVC Elbow 45°pipe Fitting Injection MouldCavity: 10 cavitiesMould size:50mmMould steel:Germany2316 china2316 or4cr13 for the cavity and coreGate :direct gatemould structure:Angle pinHardness of core/cavity: HRC 40-45°degree after vaccum heat treatmentInjection moulding machine: 320T Pvc injection problem and the solution1. Lack of material:The phenomenon that the mould can not be filled often occurs in the process of injection pipe fittings. When the injection molding machine just started to work, due to the...

News

Category:

-

[industry news]These safety issues must be paid attention to when injection...

2024-06-29 16:59:39

Case

Category:

Video

Category:

Download

Category:

No search results found!

Job

Category:

No search results found!

Featured Products

No search results found!

WhatsApp

WhatsApp Phone

Phone