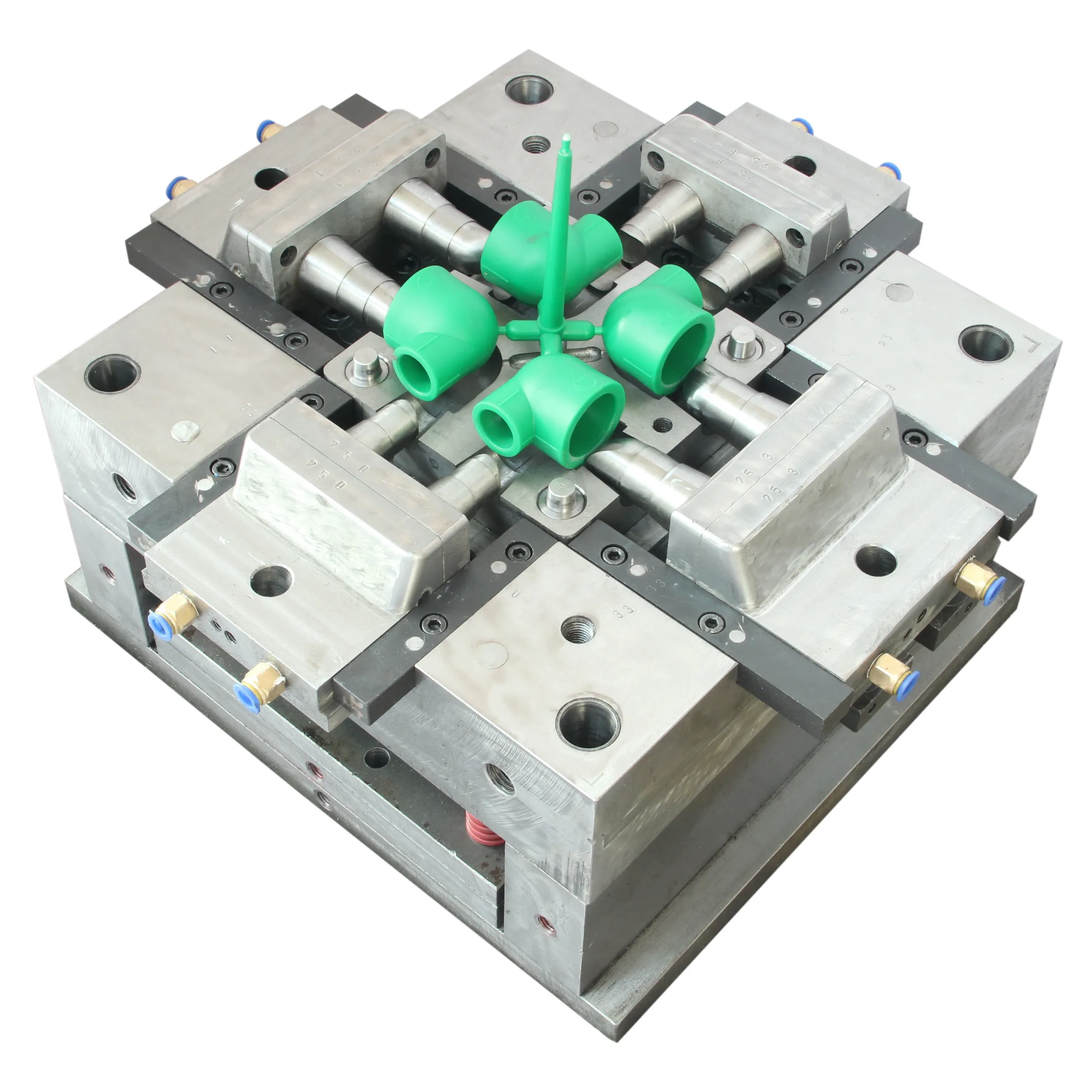

Pp-R90 Degree Elbow Mold

PP-R 90-Degree Elbow Mold: Design and Functionality A PP-R 90-degree elbow mold is a precision tool used in the injection molding process to manufacture polypropylene random copolymer (PP-R) pipe fittings, specifically 90-degree elbows. These fittings are essential in plumbing and HVAC systems, enabling smooth directional changes in piping networks while maintaining flow efficiency and pressure resistance. The mold’s design and construction play a critical role in ensuring the quality, durability, and dimensional accuracy of the final product. Key Features of the PP-R 90-Degree Elbow Mold 1. Material and Durability The mold is typically made from high-grade tool steel, such as P20, H13, or stainless steel, to withstand high injection pressures and prolonged use. Hardened steel components enhance wear resistance, ensuring a long service life even under continuous production cycles. 2. Precision Engineering The mold cavity and core are CNC-machined to exact specifications, guaranteeing tight tolerances (typically within ±0.02mm) for consistent fitting dimensions. The 90-degree bend angle must be precisely maintained to ensure proper alignment when installed in piping systems. 3. Cooling System Design Efficient cooling channels are integrated into the mold to regulate temperature during the injection process. Uniform cooling minimizes warping and internal stresses in the PP-R elbow, improving product consistency and reducing cycle times. 4. Ejection Mechanism The mold incorporates ejector pins or sleeves to smoothly release the molded elbow without deformation. Proper ejection design prevents surface defects and ensures smooth demolding, even for thicker-walled fittings. 5. Surface Finish The cavity and core surfaces are polished or textured to achieve the desired finish on the PP-R elbow. A smooth interior surface reduces friction in fluid flow, while a matte exterior may be preferred for handling and aesthetics. Production Process The PP-R material is heated to a molten state and injected into the mold under high pressure. After filling the cavity, the material cools and solidifies into the elbow shape. The mold then opens, and the finished fitting is ejected. Post-processing, such as deburring or quality inspection, may follow. Applications PP-R 90-degree elbows are widely used in hot and cold water systems, industrial pipelines, and chemical transport due to their corrosion resistance, thermal stability, and leak-proof joints. The mold must produce fittings that meet international standards (e.g., ISO 15874, DIN 8077). Conclusion A well-designed PP-R 90-degree elbow mold ensures high productivity, dimensional accuracy, and long-term reliability of the fittings. Its robust construction, precision engineering, and efficient cooling system contribute to cost-effective manufacturing while maintaining the high performance expected in modern piping systems.

Products

Category:

-

PP Collapsible Elbow Pipe Fitting Mould

Category: PP pipe fitting moldBrowse number: 580Number:Release time: 2025-09-16 23:46:09PP Collapsible Elbow Pipe Fitting MouldItem name : PP collapsible elbow 90º pipe fitting mouldCavities:16cavitiesMaterial:PPmold structure: Oil cylinder structureCavity / core steel :2738 or718for the cavity and coreHardness of core/cavity: HRC 40-45 degreeafter vaccum heat treatmentInjection molding machine:380T Taizhou Huangyan Hongjin plastic mould1、 Specializing in plastic mold manufacturing, products include: PPR PVC PP PE and other pipe mold, daily necessities mold, turnover box mold, plastic valve mold, bottle mold, etc2、 Production capacity: mold design,... -

40mm PPR Elbow 90 Degree Pipe Fitting Mould

Category: PPR pipe fitting moldBrowse number: 498Number:Release time: 2025-10-23 18:12:1040mm PPR Elbow 90 Degree Pipe Fitting MouldMould name: 40mm PPR Elbow 90 Degree Pipe Fitting MouldCavity:2 cavitiesMould size:20-50mmMould steel:2738 or 718for the cavity and coreGate :direct gatemold structure: Diagonal guide column slider structureHardness of core/cavity: HRC 32-45 degree after vaccum heat treatmentInjection molding machine:250TTaizhou Huangyan Hong Jin mould Co., Ltd was established in 2002.We are professional in design and manufacture the pipe fitting mould for more than 23 years.We are looking forward to long cooperation with you.Following is the main information fo...

News

Category:

No search results found!

Case

Category:

Video

Category:

No search results found!

Download

Category:

No search results found!

Job

Category:

No search results found!

Featured Products

No search results found!

WhatsApp

WhatsApp Phone

Phone