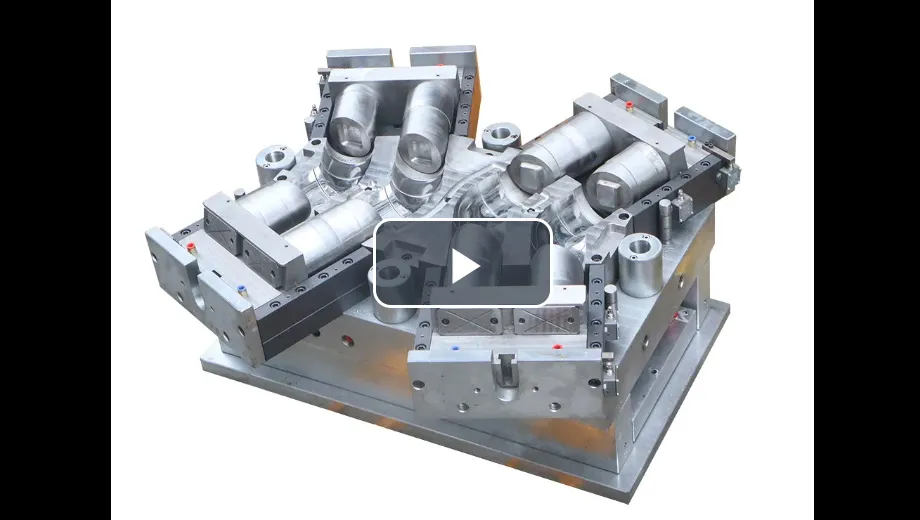

Slant Tee Pipe Fitting Mold

Slant Tee Pipe Fitting Mold: Design, Functionality, and Applications A Slant Tee Pipe Fitting Mold is a specialized tool used in the manufacturing of slant tee pipe fittings, which are essential components in piping systems for redirecting fluid flow at an angle. These molds are precision-engineered to produce high-quality fittings with consistent dimensions, durability, and leak-proof performance. Below is a detailed overview of the design, functionality, and applications of slant tee pipe fitting molds. 1. Design and Construction Slant tee pipe fitting molds are typically made from high-grade steel or aluminum to withstand high-pressure injection molding processes. The mold consists of two primary halves—the core and the cavity—which form the internal and external shapes of the fitting. Key design features include: - Precision Machining: The mold is CNC-machined to ensure accurate angles (commonly 45° or 30°) and smooth surfaces, minimizing defects like burrs or warping. - Cooling Channels: Integrated cooling systems regulate temperature during production, reducing cycle times and improving efficiency. - Ejection Mechanism: Automated ejector pins or plates ensure easy removal of the finished fitting without damage. - Venting System: Proper venting prevents air traps, ensuring complete material filling and reducing porosity. 2. Functionality The mold operates within an injection molding machine, where molten material (such as PVC, CPVC, PP, or ABS) is injected under high pressure. The process involves: - Clamping: The mold halves are securely closed. - Injection: Molten plastic is forced into the mold cavity. - Cooling: The material solidifies into the desired shape. - Ejection: The finished slant tee is removed for trimming and quality checks. The mold’s design ensures consistent wall thickness, proper joint alignment, and smooth interior surfaces to optimize flow efficiency. 3. Applications Slant tees are widely used in plumbing, irrigation, chemical processing, and HVAC systems where angled flow diversion is required. The mold must accommodate varying sizes (e.g., ½" to 12" diameters) and pressure ratings (Schedule 40/80). 4. Advantages of Quality Molds - Durability: High-grade materials extend mold lifespan. - Precision: Ensures fittings meet industry standards (e.g., ASTM, ISO). - Cost-Efficiency: Reduces material waste and production downtime. Conclusion A well-designed slant tee pipe fitting mold is critical for producing reliable, high-performance fittings. Its precision engineering, robust construction, and efficient functionality make it indispensable in modern piping systems. Manufacturers prioritize quality molds to ensure consistent output and long-term operational reliability.

Products

Category:

-

PVC Reducing Socket Pipe Fitting Mould

Category: PVC pipe fitting moldBrowse number: 601Number:Release time: 2025-09-17 00:08:35PVC Reducing Socket Pipe Fitting MouldMould name: PVC Reducing Socket Pipe Fitting MouldCavity: 6 cavitiesMould size:75x50 110x50 110x75Mould steel:Germany2316 china2316 or4cr13 for the cavity and coreGate :direct gatemould structure:Oil cylinderHardness of core/cavity: HRC 40-45°degree after vaccum heat treatmentInjection moulding machine: 400 T Taizhou Huangyan Hong Jin mould Co., Ltd was established in 2002.We are professional in design and manufacture the pipe fitting mould for more than 23 years.We are looking forward to long cooperation with you.Followin...

News

Category:

-

[industry news]Exploring the Advantages of PE Pipe Fitting Moulds in Modern...

2024-08-28 11:49:29

Case

Category:

No search results found!

Video

Category:

Download

Category:

No search results found!

Job

Category:

No search results found!

Featured Products

No search results found!

WhatsApp

WhatsApp Phone

Phone